Welding is an essential process in industrial production. Since its inception, the technology has undergone numerous technological revolutions.

1. Resistance Welding

This method is used to weld thin metals. The workpiece to be welded is clamped between two electrodes, and a high current is applied to melt the surface contacted by the electrodes. This process is achieved by heating the workpieces.

The workpieces are prone to deformation. Resistance welding welds from both sides of the joint, while

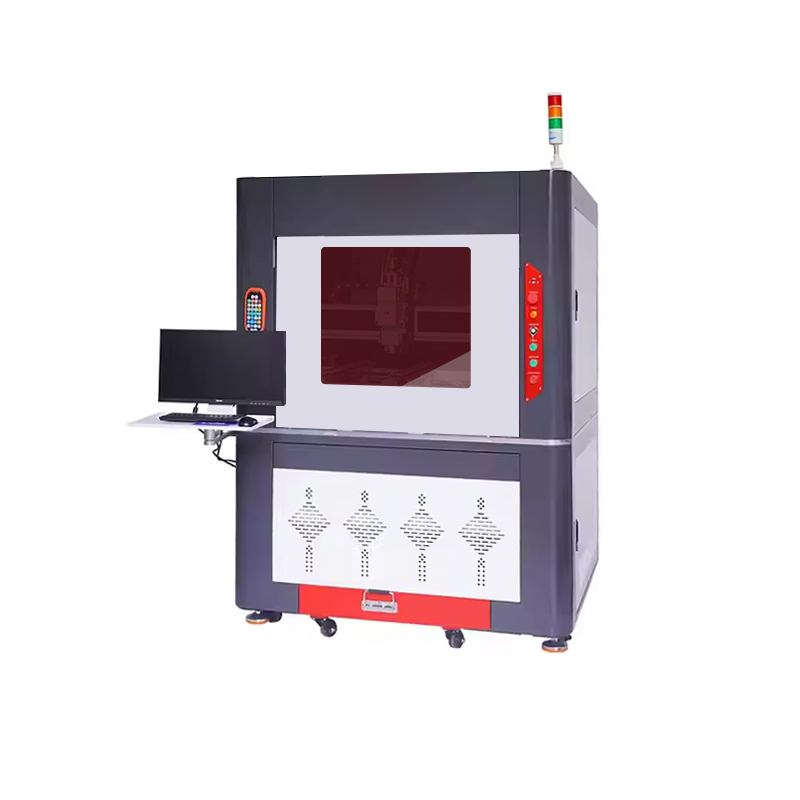

Laser Cutting Machine only weld from one side. The electrodes used in resistance welding require frequent maintenance to remove oxides and metal adhering to the workpieces. Laser

Cutting Machine do not contact the workpieces when overlapping thin metal bars. Furthermore, light can penetrate areas inaccessible to conventional welding, resulting in faster welding speeds.

2. TIG Welding

This method uses non-consumable electrodes and protective gases. It is commonly used to weld thin workpieces, but welding speeds are relatively slow, and the heat input is much greater than in Enclosed Fiber Laser Cutting Machine, which can easily cause deformation. 3. Plasma Arc Welding

Similar to argon arc welding, its torch generates a smaller arc to increase arc softness and specific energy. It is faster than argon arc welding, but inferior to electric arc welding.

4. Electron Beam Welding

This method uses a beam of accelerated, high-energy, high-density electrons to strike the workpiece. The main drawback of electron beam welding is that it requires a high vacuum to prevent electron scattering. The equipment is complex, and the size and shape of the welded parts are limited by the vacuum system. Butt welds also have strict assembly quality requirements. Non-vacuum electron beam welding can also be performed, but poor focusing due to electron scattering can affect the results. Electron beam welding also has magnetic deflection and X-ray issues. Electrons are inductively charged and are affected by electromagnetic field deflection, so it is necessary to demagnetize the workpiece before welding. Electric arc welding, on the

Other hand, does not require a vacuum system or pre-weld demagnetization of the workpiece. Electron beam welding can be performed in air, allowing it to be operated within a production line network. It can also weld permanent magnet materials.